Mongolian Prosthetics

Awareness. Understanding. Technology. Accessibility. Progress.

The land of endless blue skies is also a land of endless opportunity. Our goal at Mongolian Prosthetics is to make sure that opportunity is available to all. Our mission is to expand current understanding and awareness of the need for prosthetics in Mongolia, provide educational opportunities to grow the field of biomedical engineering, and improve access to comfortable and affordable prosthetics and sockets by leveraging cutting-edge 3D-printing and scanning technology.

Quick Facts

There are approximately 56,000 people in Mongolia living with disabilities requiring prosthetic or assistive devices

Mongolia’s economy is largely based on physical labor

~3% of the population in need is currently served by Mongolia’s domestic prosthetic manufacturers

Affordable prosthetic options are resin-based, non-custom, static prosthetics from China (160.00 USD)

Average annual income in Mongolia is approximately 1,896.00 USD

Effective and customizable 3D printed prosthetic hands/arms have been produced for less-than 50.00 USD in under 24 hours.

Technology

FDM 3D Printers

Low-cost, reliable, easy-to-use, and capable of creating functional parts out of several materials with details down to 50 micron (.05 mm) resolutions, these printers are the backbone of our project and can act as both mobile rapid manufacturing centers and incredible educaitonal tools to get students and proffesionals of all ages interested in prosthetics, engineering, and accessibility. Plus….3D printing is cool.

Peel 1 Handheld 3D Scanner

Our Peel 1 3D scanner is an invaluable tool and they key piece of hardware that allows us to provide comfortable, custom-fit prosthtetics that recipients are able to use all day. It allows us to generate digitized models of residual limbs with an accuracy of .25 mm in minutes and export those models in a variety of file formats that we can then use to create customized prosthetic sockets to maximize patient comfort while keeping costs and design/CAD time low. Peel3D

Computer Aided Design (CAD)

3D printers without 3D models are like a bike without wheels. In order to create custom sized and fit prosthetics and sockets, we work from our existing designs and 3D scans to quickly create personalized prosthetics that are both effective and comfortable.

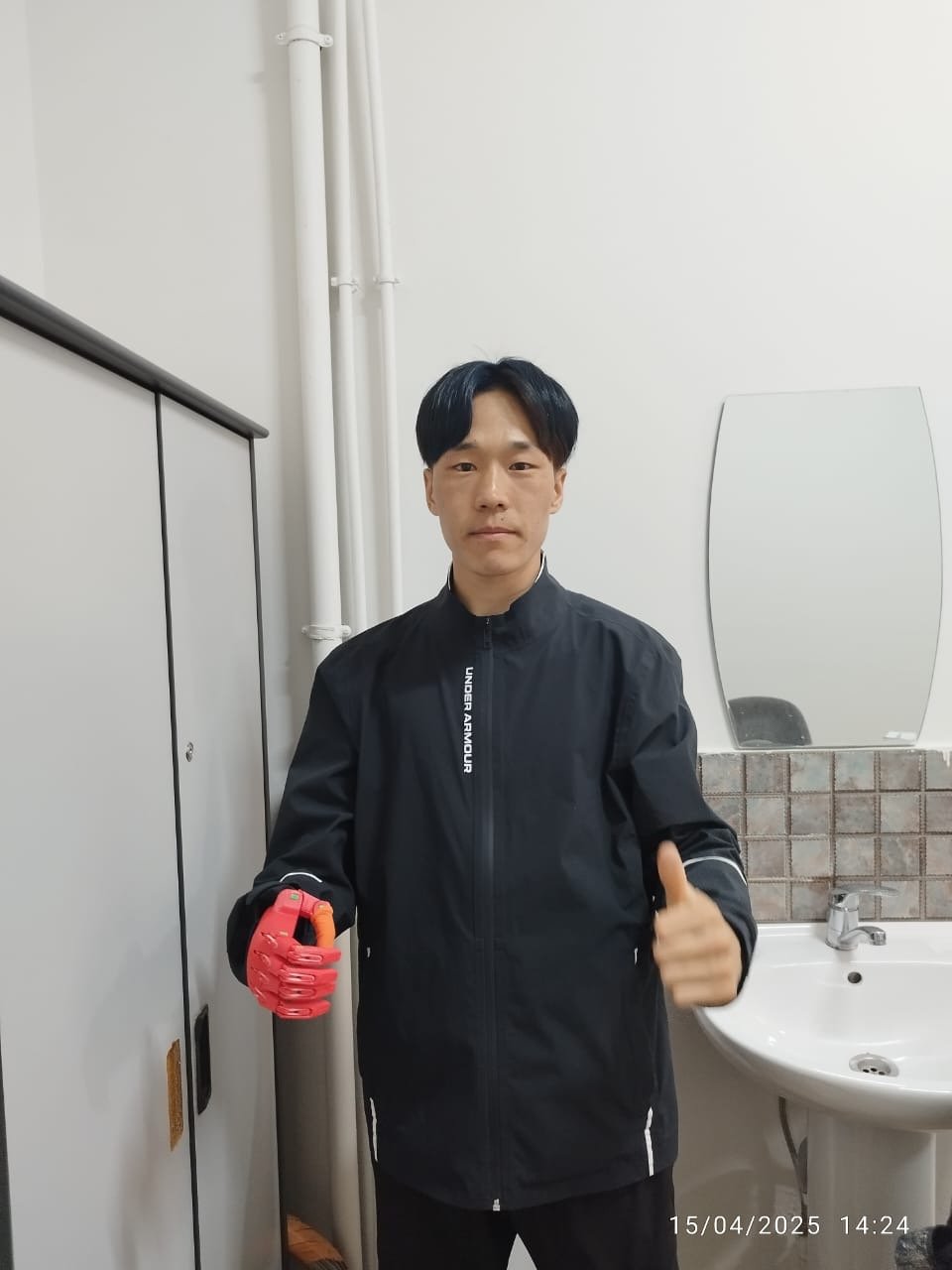

Sustainable Production of Custom Prosthetic Hands in Mongolia

One of the primary goals of the Mongolian Prosthetics Fulbright Project has been successfully achieved! After months of research, collaboration, and invaluable partnerships, we have developed and introduced a procedure to create articulated, custom hand prosthetics in Mongolia in less than two days for under $40.

With the support of the National Rehabilitation Center of Mongolia, the Oddariya Foundation, and the Fulbright Program, we have produced and tested several devices. These prosthetics have been proven to withstand Mongolia’s unique environmental conditions while significantly improving patients' ability to perform everyday tasks.

A Simple Yet Impactful Innovation

One of the most exciting aspects of this achievement is its accessibility:

Quick to Learn: The process can be mastered with just 1–2 days of training

Available Equipment: Uses tools already present in all seven publicly funded prosthetics workshops in Mongolia

Major Upgrade: Replaces non-functional silicone sleeves with articulated, usable prosthetics

Low Cost: Costs nearly the same as the silicone models but provides greater functionality and dignity

By providing usable, articulated prosthetic hands, we are not only improving the quality of life for recipients but also helping to reduce stigma and promote inclusivity for individuals with limb differences in Mongolian society.

Key Stats:

Cost: Less than $40

Production Time: 2 days (from scan to fitting)

Equipment: One FDM 3D printer

Assembly: One person can make it from start to finish

This breakthrough means that more individuals in need—especially in underserved communities—can now access functional prosthetics without the financial burden of traditional options. By leveraging affordable materials and open-source designs, we’re proving that practical, life-changing prosthetics don’t have to come at a high price.

This is just the beginning! We are excited to keep innovating and expanding access to prosthetic solutions in Mongolia and beyond.